Hardox chute Hardox chute

Manufactured using wear resistant steel the Hardox chute offers a longer service life.

|

Pause during processing Pause during processing

The Pause functionality can be used mid bale from the Synchro system. When paused, the bale is moved away from the cross beater and processing stops immediately.

|

Adjustable bale restraint Adjustable bale restraint

Variable position bale restraint (adjusted via WIFI control) ensures an even flow of material into the discharge fan.

|

Automatic bale hood Automatic bale hood

Bale hood raises automatically when machine is being loaded

|

3rd Generation Dual Chop System 3rd Generation Dual Chop System

A unique larger diameter crossbeater and a 40% larger open area at the screen.

|

Bale retention beam Bale retention beam

The swinging bale retention beam on the tailgate can be adjusted between one loading and six operating positions.

|

Rear tailgate switch Rear tailgate switch

Load bales without having to return to the tractor cab, ideal when removing netting or wrap.

|

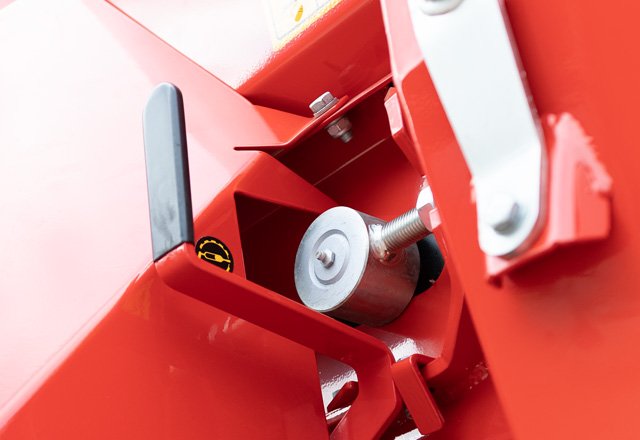

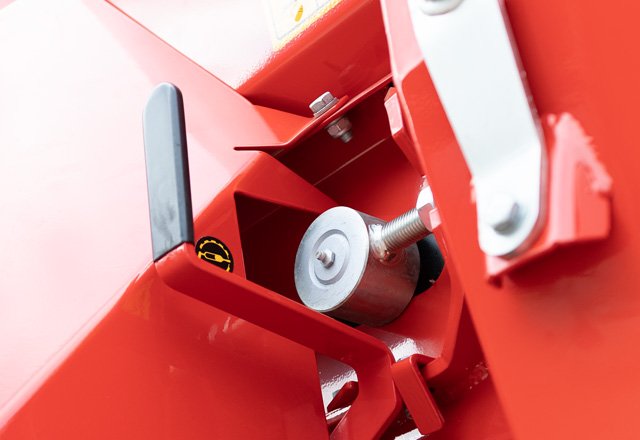

Superior finish Superior finish

Achieved through investment in the latest pre-paint preparation and double powder coat paint system. Nuts and bolts are either galvanised or stainless steel.

|

Stone trap Stone trap

Stones and debris can quickly be removed from the drop down hatch at the rear of the machine.

|

Wider feed slide Wider feed slide

An wider delivery slide improves delivery of material against a feed barrier.

|

Synchro System Synchro System

Pre-programmed to suit high flow and lower flow applications like bedding for high flow and dispensing silage for lower flow.

|

Robust gear changer Robust gear changer

High specification gear box with high/low fan speed gear pre-selection.

|

Centralised lubrication Centralised lubrication

A greasing bank and auto chain lubrication (optional on 8200) make routine maintenance easier.

|

Hardox chute

Hardox chute Pause during processing

Pause during processing Adjustable bale restraint

Adjustable bale restraint Automatic bale hood

Automatic bale hood 3rd Generation Dual Chop System

3rd Generation Dual Chop System Bale retention beam

Bale retention beam Rear tailgate switch

Rear tailgate switch Superior finish

Superior finish Stone trap

Stone trap Wider feed slide

Wider feed slide Synchro System

Synchro System Robust gear changer

Robust gear changer Centralised lubrication

Centralised lubrication

HydroShield Dust Suppression

HydroShield Dust Suppression Tailgate Extension

Tailgate Extension Hydraulic Filter

Hydraulic Filter Clevis Drawbar and Jack

Clevis Drawbar and Jack